One must start with the general details in order to assess whether a solar street pole is a qualified product.

Solar street poles are typically tapered. A plate cutting machine is used to cut them into trapezoidal plates according to their corresponding dimensions, and a bending machine is used to roll them into a tapered tube. When evaluating their quality, keep the following points in mind:

1. There will be a joint in the rolled tapered tube after the steel plate is bent. This joint needs to be sealed using a submerged arc welding machine. This weld is very important. If the rollers of the submerged arc welding machine are not synchronized, the steel plates on both sides will be uneven, affecting the appearance. Observe the weld for pinholes. If pinholes are present, even after galvanizing and powder coating, rusting in the pinhole area is still unavoidable.

2. The welding at the flange and power supply port must be even and smooth. Since the entire support of the solar street pole rests on the bottom, the weld joint must be wide and free of any gaps. Since a lot of weld slag is frequently splattered during manual flange welding, careful cleaning is essential to avoiding major aesthetic damage.

Usually, two screws are used to fasten the solar street pole arm to the pole. Verifying the clearness of the wiring hole between the arm and the pole is crucial. Some light pole manufacturers use flame cutting to make the wiring hole in an attempt to save time and effort. This causes weld slag to surround the inner wall of the hole, making on-site installation labor-intensive and time-consuming.

3. Check the galvanization of the solar street pole. The thickness of the galvanized layer should be uniform. Uneven thicknesses on one pole, while not a major issue, indicate a defect in the galvanizing process. Also, check the gloss. Good galvanization will have a silvery sheen under sunlight; a dull, lackluster surface indicates a substandard product that will rust quickly.

4. Powder coating is the final step in the production of the finished solar street pole. Its rust-proof strength is second only to galvanizing, but it is also crucial. A good powder coating process looks smooth and uniform, without any missed spots, and upon close inspection, there are no discoloration marks. To test the adhesion of the powder coating on the pole, you can use a sharp steel tip to forcefully scratch a line on an unimportant area, such as under the flange. Observe whether any powder coating lifts off either side of the scratch. If not, the adhesion is acceptable. If there is lifting, it indicates a problem with the powder coating process. This can lead to large-scale peeling of the powder coating during transportation, affecting the appearance and significantly reducing the rustproof lifespan.

The above points cannot fully summarize the entire process, but if all of these points are satisfactory, then the solar street pole can be considered a qualified product.

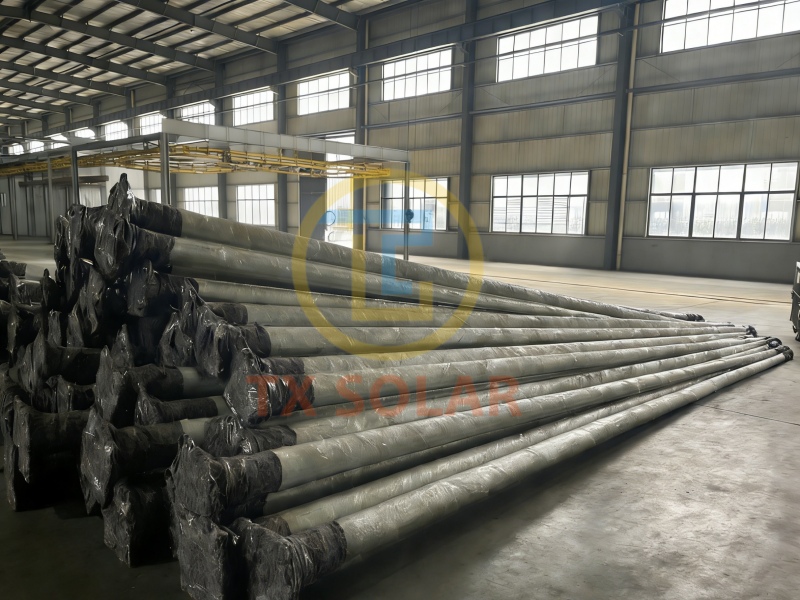

Tianxiang Streetlight Factory has been exporting streetlight poles overseas for twenty years, and they are highly favored by international customers. Our products support customized height and diameter, and are easy to install. We offer competitive prices and stable delivery, with discounts for bulk orders. We sincerely invite engineering contractors and distributors to cooperate with us!

Post time: Dec-23-2025