LED street lights are becoming more and more popular due to their advantages of energy saving, long life, and environmental protection. However, ensuring its quality and performance is critical to providing the best possible lighting solution. A commonly used method to evaluate LED street lights is the integrating sphere test. In this blog post, we will explore how to perform integrating sphere testing on LED street lights and why it is an important step in the quality assurance process.

What is an integrating sphere test?

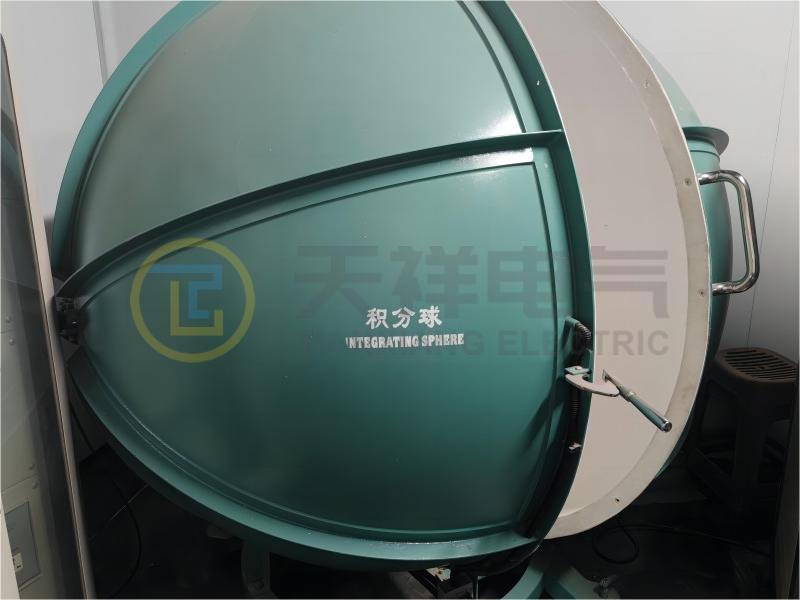

An integrating sphere is a hollow chamber with a highly reflective inner surface and multiple ports for light input and output. It is designed to collect and evenly distribute light, making it an ideal tool for evaluating the performance characteristics of LED street lights. The integrating sphere test measures various parameters of LED street lights, including luminous flux, color temperature, color rendering index (CRI), and luminous efficacy.

Steps for integrating sphere test on LED street lights:

Step 1: Prepare LED Street Lights for Testing

Before conducting the integrating sphere test, please make sure that the LED street light is functioning properly and installed securely. Clean the outside surface of the lamp to remove any dirt or debris that may affect the test results.

Step 2: Calibrate the Integrating Sphere

Calibration of the integrating sphere is critical for accurate measurements. This includes ensuring that the reflective coating of the sphere is in good condition, verifying the stability of the light source, and verifying the accuracy of the spectroradiometer.

Step 3: Place the LED Street Light in the Integrating Sphere

Place the LED street light firmly inside the port of the integrating sphere, making sure it is centered and aligned with the optical axis of the sphere. Make sure that no light leakage occurs during the test.

Step 4: Test

After the LED street light is correctly positioned, start the test. The integrating sphere will capture and evenly distribute the emitted light. A spectroradiometer connected to a computer will measure parameters such as luminous flux, color temperature, CRI, and luminous efficacy.

Step 5: Analyze Test Results

After the test is complete, analyze the data collected by the spectroradiometer. Compare measured values with stated requirements and industry standards. The analysis will provide insight into the quality, performance, and potential improvements of LED street lights.

Importance and benefits of integrating sphere testing:

1. Quality Assurance: Integrating sphere testing ensures that the LED street lights meet the required industry standards. It enables manufacturers to detect any design flaws, component failures, or performance issues early, thereby improving product quality.

2. Performance optimization: The integrating sphere test helps manufacturers optimize the performance of LED street lights by measuring parameters such as luminous flux and luminous efficacy. This increases energy efficiency, reduces operating costs, and improves lighting quality.

3. Customer Satisfaction: Integrating sphere testing ensures that LED street lights meet expected levels of brightness, color rendering, and uniformity. Ensure customer satisfaction by providing lighting solutions that meet customer requirements and expectations.

In conclusion

Integrating sphere testing plays a vital role in evaluating the quality and performance of LED street lights. By conducting this testing, manufacturers can ensure their products meet industry standards, optimize performance, and increase customer satisfaction. With the growing demand for energy-efficient lighting, integrating sphere testing is still an important step in developing high-quality LED street lights.

If you are interested in LED street light, welcome to contact LED street light factory Tianxiang to read more.

Post time: Aug-31-2023